PPGI Tile Roofing Sheet Cold Forming Machine

Basic Info

Model No.: KYT

Product Description

PPGI Tile Roofing Sheet Cold Forming Machine

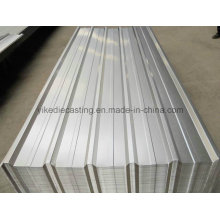

This Roofing sheet fit for all type of roofing application from monestic gardon shed, garage roof and villa. The profile of the tile roofing sheet has depth of 28mm, proved 5 tiles across the width of each sheet. Each individual tile width is 200mm. And it can fit both 1000mm and 1250mm PPGI and GI coil. If any size you want to change, we can special design for you. This machine has pre cutter at feeding table, and you can cut the sheet after a batch of size. Machine can automatically measure the sheet, and cut the size you want and stop when machine finish.

Parameters for Metal Roofing Sheet Roll Forming Machine

- Suitable Raw Material: Color Steel Coil, Galvanized Coil, Aluminum Coil and So on.

- Raw Material Width: Design as Customer Require.

- Raw Material Thickness: 0.3-0.7mm.

- Drive System: by chain.

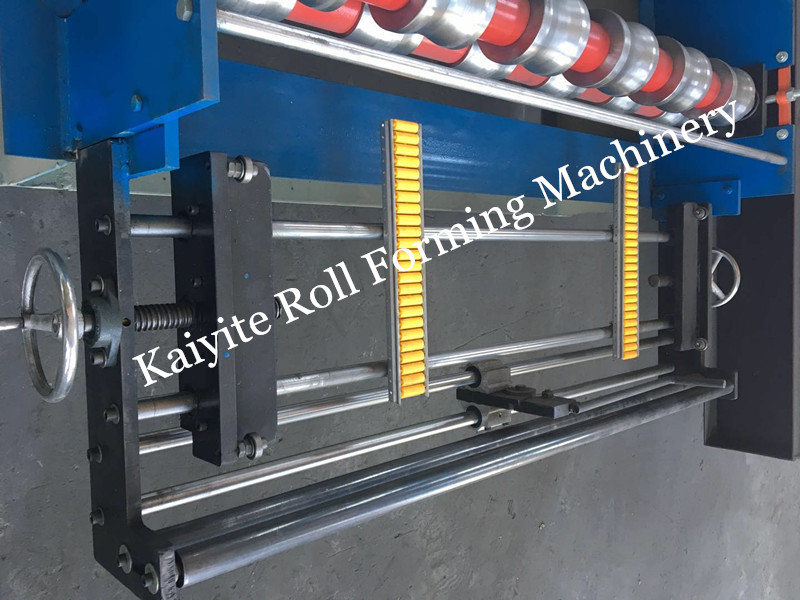

- Forming Roller: 12 Raws.

- Roller Material: ¢70mm Shaft 45# Steel, Hard Chrome

- Motor: 4KW for Driving, and 4KW for Cutting.

- Machine Apperance: About 7200x1400x1430mm (LxWxH).

- Machine Voltage: 380v, 50Hz, 3Phase

- PLC Brand: Delta Brand with Touch Screen

- Working Speed: 4m/min

- Wall Sheet Thickness: 18mm

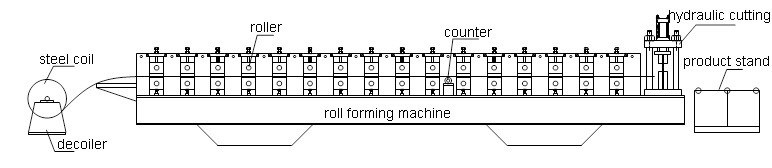

Working Process for Glazed Tile Roll Forming Machine

5T Uncoiler - Feeding Table - Roll Forming Rollers -PLC Control System - Hydraulic Pressing - Hydraulic Cutting - Run Out Table

Component for Roof Tile Forming Machine

Manual Uncoiler: 1 piece; Main Forming Machine: 1 set;

Control Box: 1 set; Hydraulic System: 1 piece;

Run Out Table: 1 piece; Spare Pars: 1 box

Details of Roof Roll Forming Machine:

Working Video For Metal Roof Tile Forming Machine

To Know More About Steel Sheet Forming Machine, Please contact:

Product Categories : Roof And Wall Panel Roll Forming Machine > Glazed Tile Roll Forming Machine